What is Investment Casting?

Upload Time:

Sep 29, 2023

What is Investment Casting?

What is Investment Casting?

Investment casting is a manufacturing process in which a wax pattern is coated with a refractory ceramic material. Once the ceramic coating material is dry and hardened, the wax is melted out and leaves an internal cavity the shape of the final product’s geometry. Molten metal is poured into the cavity where the wax pattern was. The metal solidifies within the ceramic cavity, cools, and the ceramic is removed from the metal casting. The result of this process is a net to near-net precision metal component which can be used for a broad range of applications in various industries.

Why is it Called Investment Casting?

The ancient art and science of investment casting is also known as the lost wax process. Investment casting was developed over 5500 years ago and can trace its roots back to both ancient Egypt and China. Parts manufactured in industry by this process include dental fixtures, gears, cams, ratchets, jewelry, turbine blades, machinery components and other parts of complex geometry.

What is the Investment Casting Process?

Investment casting is a manufacturing process in which a liquid material is poured into a ceramic mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is the casting, which is broken away from the ceramic mold to complete the process. The steps within the investment casting process are as follows:

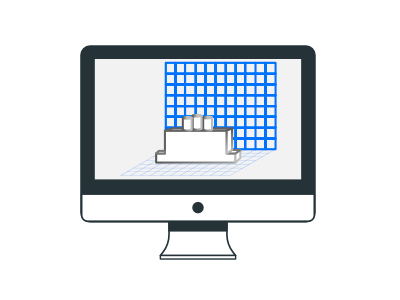

Step 1: Engineering Review

-

The first step of this manufacturing process begins with a full Design For Manufacturing (DFM) review with the customer.

-

This would include an evaluation of print dimensions as it relates to the investment cast process, wax injection mode build considerations such as gate placement, post-case material requirements and expected tolerances for fit, form and function of the part, and final inspection criteria to determine a mutually acceptable part.

Step 2: Mold Design & Build

-

The process begins with a precision-engineered wax injection mold to produce wax patterns representing the final part.

-

These design considerations are discussed with the mold builder and a mold design is created.

-

Our wax injection molds are built here at Aero Metals at our in-house mold shop.

-

The molds are designed and built to reproduce millions of wax parts over its lifetime.

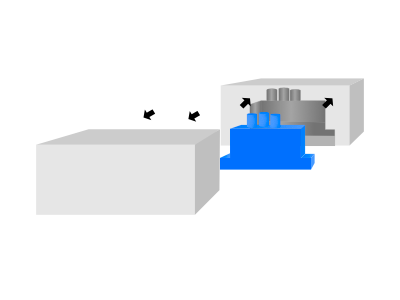

Step 3: Wax Pattern

-

The wax injection mold is quantified to run production and brought to the Wax Room for injection and assembly.

-

Anywhere from one to 100 patterns are injected and placed or glued onto a pre-fabricated wax runner system known as a “tree” in our process.

-

The populated tree of wax parts is also known a cluster (of parts).

-

The tree cluster is then sent to the Dip Room for the next part of the process.

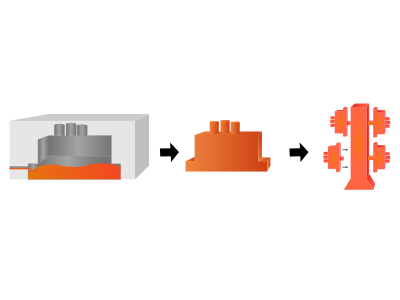

Step 4: Ceramic Mold Construction

-

The wax tree is dipped and completely enveloped into ceramic slurry, taken out, then completely coated in sand to create the first layer of shell, and then dried.

-

This enveloping process of dip and sand is repeated 6 or 8 times with a drying period between each one.

-

By repeating this process, it creates a lamination effect building a strong ceramic shell around the wax pattern as known as “investment”. The shell now runs through our drying system for 24 to 36 hours before removing the wax from the shell.

Step 5: De-waxing

-

The shell, which consists of the wax pattern and its coating of ceramic and sand, is placed into an autoclave to quickly remove the wax under extremely high pressure and steam heat.

-

This vessel helps to hold the shell in place and the steam heat quickly melts the wax out creating an empty ceramic mold, hence the name “lost wax” casting.

-

The ceramic shell is then moved to the foundry ovens to start the casting process.

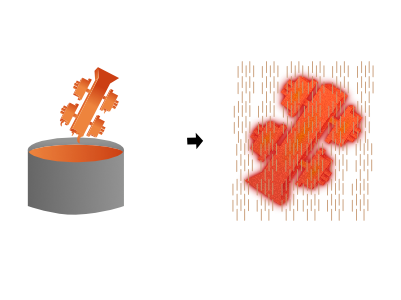

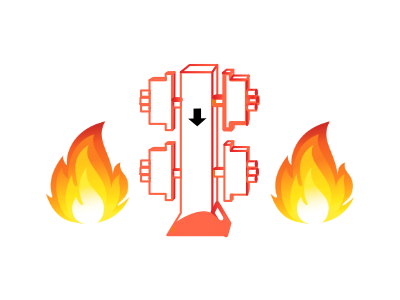

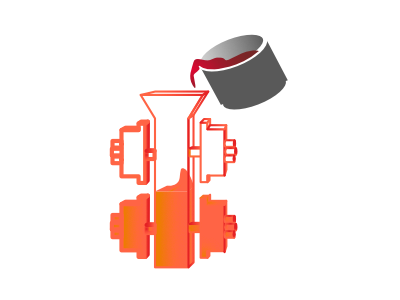

Step 6: Foundry & Pouring

-

The mold is then placed into a high temperature oven, approximately 1000°C (1832°F), to cure (cristobalite) the ceramic mold and prepare it for accepting molten metal.

-

The cured ceramic mold is removed from the hot oven and molten metal is immediately poured into the mold cup and its subsequent gating system, completely filling out the mold cavity with metal.

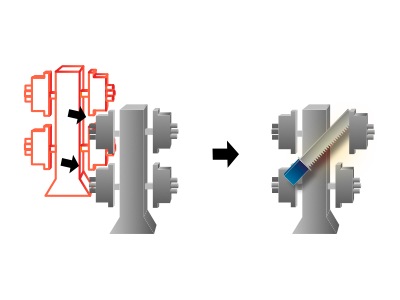

Step 7: Shell & Casting Removal

-

After the metal has cooled to the touch, the ceramic mold shell can be broken away from the part(s), and the casting(s) removed from, the now metal, tree.

-

The ceramic shell is brittle and typically broken free by using water jets, vibration, and other methods.

-

Once the tree is clean of the ceramic, the parts are removed from the gating system by either cutting off with a saw with vibration or liquid nitrogen.

Step 8: Finishing

-

Often, the part’s gate is removed by a grinding or machining post-cast operation.

-

Further finishing such as heat treatment to anneal before machining, plating, or harden is completed before final inspection and shipping to the customer.

Relevant News